1 Comprehensive introduction

1.1 Overview

The air conditioner in the DKT cabinet is based on the actual use of the customer in Baoying County Xingyuan Electric Appliance Factory. It is aimed at the radiant heat conduction, uneven heating, unsatisfactory dehumidification effect, and thermal damage to the components in the cabinet according to the actual use of the customer. Insufficient, and developed a brand-new heat-generating air conditioner. This product can be widely used in various power distribution cabinets, terminal boxes, control panels, museums and other occasions that have strict requirements on ambient temperature and humidity.

According to the size of the control range, there are several models of DKT-50, DKT-100, DKT-150, DKT-200 to choose from (please refer to other data sheets of technical parameters).

1.2 Brief description of working principle

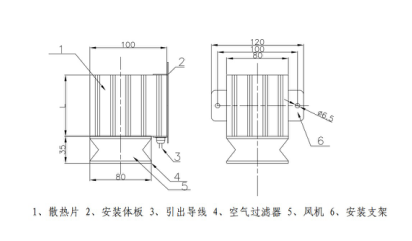

This product is composed of PTC ceramic heating element, radiator, axial fan, dust-proof net, mounting bracket, etc.

PTC ceramic heating element works by using the characteristic of PTC resistivity changing with temperature. When the temperature is low, the resistance of the PTC ceramic heating element is small, the heat generation is large, and the temperature rises faster. With the increase of temperature, the resistance of the PTC ceramic heating element becomes larger, the heat generation becomes smaller, and the temperature rise becomes slower; finally realizes constant temperature heating (After stabilizing the surface temperature of the radiator, please refer to the other data sheets of the technical parameters).

In order to change the pure heat radiation heat conduction of conventional heaters, this product is equipped with a miniature axial flow fan. There are two functions: when the PTC ceramic heating element is heated, the miniature axial flow fan starts at the same time to form heat convection in the area, so that the heat field in the control area is evenly distributed. When heat accumulation or local temperature rise occurs, only the micro axial fan is activated for local heat dissipation (this function needs to be used in conjunction with our company's dedicated controller WSK-TH and WSK-Z(TH)).

The radiator is a special aluminum profile for this product, and the surface treatment is anodized black. The cross-section is designed by professional calculations, which can ensure the rapid, uniform and reasonable distribution of heat transfer as much as possible.

The dust screen is installed at the air inlet of the miniature axial flow fan, and the DKT can effectively filter the dust in the control area when it is working. It is helpful to prevent breakdown and leakage accidents caused by dust and dirt on the surface of the component.

The molded mounting bracket can be used for screw mounting and rail mounting, allowing users to install quickly and simply.

2 technical parameters

2.1 Technical parameters

|

project

|

technical parameter

|

|

Operating temperature

|

- 10 deg.] C ~ 65 deg.] C

|

|

Maximum working temperature

|

- 25 deg.] C ~ 75 deg.] C

|

|

Relative humidity

|

≤ 95 %RH

|

|

PTC working voltage (AVC)

|

220V± 10%

|

|

Fan

|

Working voltage (AVC)

|

220V± 10%

|

|

Rated frequency (Hz)

|

50

|

|

Rated current (A)

|

0.07

|

|

Power (W)

|

15.4

|

|

Speed (RPM)

|

2700/3000

|

|

Air volume (CFM)

|

26/29

|

|

Wind pressure (mmH20)

|

3.7/5.0

|

2.2 Other data

|

model

|

Weight (kg)

|

Dimensions (mm)

Length L × Width × Height

|

power

(W)

|

surface temperature

(℃ )

|

Suggested control space

|

|

DKT-200

|

1. 1 8

|

(100+38)×80×100

|

200

|

45± 2.5

|

≤ 5 m 3

|

|

DKT-150

|

0.99

|

(80+38)×80×100

|

150

|

41± 2.5

|

≤ 3.5 m 3

|

|

DKT-100

|

0.99

|

(80+38)×80×100

|

100

|

39.5± 2.5

|

≤ 2 m 3

|

|

DKT-50

|

0.99

|

(80+38)× 6 0× 6 0

|

50

|

39± 1.5

|

≤ 1 m 3

|

DKT and EKT are common, and the surface temperature and dimensions can also be customized according to the actual requirements of users.

3How to use

3.1 Shape and installation dimensions:

3.2 Wiring terminal

Two silicone rubber temperature-resistant wires are used for connection, the standard length of the lead is 500mm

4 Precautions for use

5.1 The power supply must be connected in strict accordance with the marked voltage level

5.2 The equipment should be installed vertically (the fan end faces down), and the air inlet channel should be reserved. Preferably ≥10mm.

5 Transportation and storage

The equipment should be stored in an environment with a temperature of -25℃~70℃ and a humidity of <85%, and should be placed in the original packaging, and the stack height should not exceed 5 layers. The equipment should not be stored after unpacking.

The transportation and unpacking of the equipment should not be subject to severe impact, and should be transported and stored in accordance with the provisions of GB/T15464-1995 "General Technical Conditions for Instrumentation Packaging".

6Warranty period

Within twelve months from the date of sale of the equipment, if the user complies with the requirements of the manual and the manufacturer’s seal is intact, if the equipment does not meet the specified requirements, the manufacturer will repair or replace it free of charge.